Vacuum technology sets wood in motion - bigger, higher, further!

As a partner of trade and industry, AERO-LIFT Vakuumtechnik sees itself as responsible for developing systems and equipment for furniture manufacturers, carpenters, joineries, carpenters and wood handlers that make the processing and transport of wood easy on materials, ergonomic, flexible, safe and economical - naturally using the power of vacuum lifting technology.

Handling of chipboard, OSB and MDF boards

AERO-PORO is a specialist for the "big" challenges - in the truest sense of the word. There are hardly any limits to the weight and size of the transported goods. It is a vacuum lifter with a blower for transporting OSB, MDF and chipboard as well as other air-permeable panel materials in the wood industry.

At the control panel of this load handling device, the device functions such as suction release, swivelling and chain hoist control can be carried out in two stages. The blower has a special flywheel mass to keep the load safe for a while in the event of a power failure. These vacuum lifters are very important in the wood industry. By using an AERO-PORO, one person - the crane operator - is sufficient to lift, transport, swivel and deposit the workpiece, damage-free and without assistance. An existing crane or a crane traverse can be used effectively with an AERO-PORO lifting device. Thus, this device adapts optimally to the existing transport infrastructure. Even the largest wooden panels can be transported without any problems - in fact, there is hardly any upper limit. Even with porous materials, the vacuum is easily built up.

For panel cutting with different materials or feeding of vertical saw and dividing saw

The ARO-LIFT tube lifters are suitable for feeding a vertical saw or a dividing saw with wooden panels. An easy-to-operate manual swivel device on the tube lifter enables the horizontal or vertical picking up and placing of the wooden panels on the saw. The panel can be swivelled through 90 degrees with a swivel lever.

A blower generates the necessary vacuum volume flow for safe suction and lifting of the wooden panels. The easy-to-operate gas rotary handle with safety lock for the suction-lifting and lowering-release function ensures rapid operation. To facilitate the swivelling process, swivelling with the aid of a pneumatic swivelling cylinder is available as an option. This will also be presented at the LIGNA trade fair at Stand D01 in Hall 15. Tube lifters enable the lifting and moving of porous and tight table tops for rack removal, the loading and unloading of processing machines and the processes for panel dividing saws. Goods such as furniture parts or chairs can also be transported and turned using individual vacuum lifting devices.

The AERO-LIFT tube lifters ensure flexible, somewhat easier wood transport. This product family lifts, swivels and transports materials such as chipboard, OSB, MDF, multiplex and hardwood panels starting from 50 kg and ending at 300 kg with horizontal transport. The pneumatically swivelling version has a maximum load capacity of 160 kg. The modular system of these lifting tools can be adapted to the production process. Lifting, transporting, lowering and placing - every process is gentle and fast. Employees are relieved. The material flow is improved and the added value increased. The convenient one-hand operation for the "suction-lift-lower-release" function enables quick and easy work - without effort and with an unexpected feeling of lightness. Turning and swivelling can be carried out manually or pneumatically as described above. Fast and effective handling of wooden boards and wooden elements is possible with an AERO-LIFT tube lifter for worktops, boards, sawn timber (trimmed and untrimmed), table tops, laminate, blockboards, beams, stairs and pallets. An AERO-LIFT tube lifter is flexible in the choice of the suitable suction foot or the vacuum components used in the suction plates, such as round or oval seals or suction plates with VUSS valve technology.

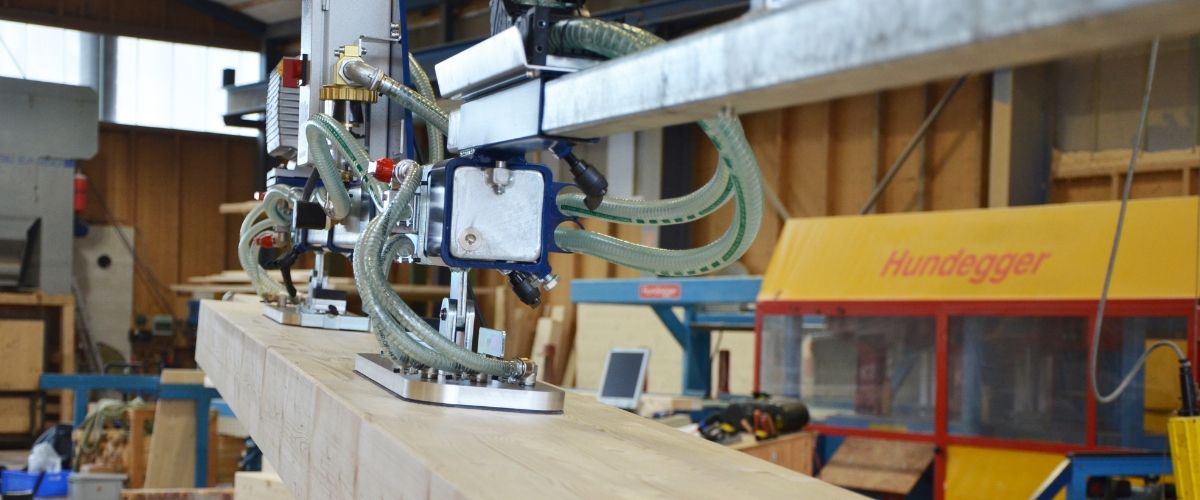

Vacuum lifter for heavy wooden planks

Lockable 3-chamber suction plates of these suction lifters ensure that planks of different widths and weights can be transported and then processed with the AERO-TIMBER without conversion time. The operator controls the functions effortlessly and has a view over the workpiece.

With this handling solution, the AERO-TIMBER minimizes the risk even with extremely heavy, bulky and overlong wooden materials. A powerful, high-quality vacuum pump "made in Germany" always provides a sufficient vacuum - even in the event of a power failure, the vacuum is maintained for a sufficient period of time. The electronic warning device with monitoring of vacuum level and power supply offers maximum safety. The extendable operating handle enables the employee to work in an ergonomic position and has an optimum view of the workpiece. The AERO-TIMBER is also available with convenient radio remote control.

Transporting enormously long and heavy wooden planks has always been one of the tasks in wood handling. The AERO-TIMBER is one of the multi-talented cranes and has been successfully used in trade and industry for years as a vacuum lifting device for handling long and heavy beams, planks, laminated timber beams, wooden elements, solid structural timber, solid wood and logs.