Moving the heaviest loads with ease

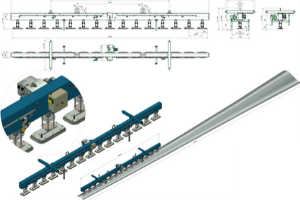

Metalworking on a grand scale

With a lifting capacity of up to 12 tons, this heavy-duty jack for metal and steel processing is still a fairly small one among the big ones. The suction plates arranged in a row allow metal plates of up to 12 m in length to be handled. However, even shorter goods to be transported can be handled easily by means of disconnectable suction circuits and swivelling external crossbars. The special feature of this heavy duty lifter is above all the special suspension. This can be held and lifted on a double bridge crane. Thanks to the electromotive rotation device, the transported goods that are held in place, including the vacuum lifter, can be rotated through 360° in the horizontal plane. This allows panels to be picked up in different horizontal positions and placed in another, rotated position. This completely eliminates the need to move the lifting device on the goods to be transported in several steps, thus allowing fast and comparatively convenient handling even with extremely long and heavy metal plates.

Demoulding on a grand scale

With a lifting capacity of 20 tons, this heavy-duty jack is not yet the largest, but it is for a very special purpose. Where most heavy-duty lifters with vacuum technology are used primarily in the construction, concrete or steel industries, this vacuum lifter proves its worth in the handling of blades for wind turbines. Until the heavy-duty lifter is used, the blades, which can be up to 100 m long, are removed from the mold shells using mechanical crane devices and retaining straps in a manual process that takes up to one hour. The use of the heavy-duty lifter reduces the time required for demoulding the oversized blades to 10 - 15 minutes and at the same time ensures a safer working process. Although a crane hook is still used directly in the working process, to which the wing is attached on the hub side, but instead of retaining straps every 10 m, only the lifting device is now placed just below the wing tip. Then the entire sash can be lifted evenly by means of synchronised chain hoists and placed on a transport rack.

Always somehow special

It is clear that heavy-duty jacks are always special in some way. Basically, a similar technology ticks in each of these giants and the methods are the same for all of these vacuum lifters. Nevertheless, all of the siblings in this division show off their individuality and demonstrate different strengths depending on the intended purpose and application. All of them can lift a great deal, and each heavy-duty vacuum lifter can also show off its specific properties and meet its own special requirements.